Description

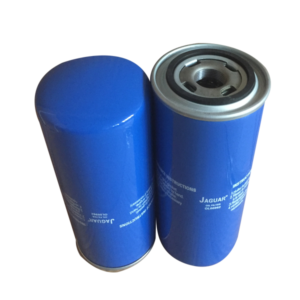

Atlas Copco Oil Filter – P/N: 1631011800

Premium OEM Oil Filtration Solution for Air Compressors

The Atlas Copco Oil Filter P/N 1631011800 is a genuine high-performance replacement oil filter engineered specifically for Atlas Copco screw air compressors and industrial rotary machines. Designed to ensure maximum equipment uptime, superior lubrication protection, and extended service intervals, this oil filter keeps your compressor running at peak efficiency under demanding operational conditions.

Key Features & Benefits

🔹 OEM-Grade Filtration: Manufactured to meet original Atlas Copco specifications, providing reliable performance and long service life.

🔹 Efficient Contaminant Capture: The filter media employs high-quality inorganic microfibers with ~25 µm filtration capability to trap particles and debris, protecting internal compressor components.

🔹 Robust Construction: Built to withstand working pressures up to 25 bar with a burst pressure of 35 bar, ensuring durability in high-pressure applications.

🔹 Reliable Bypass Valve: Integrated bypass valve opens at ~1.75 bar, maintaining flow even under heavy contamination or cold starts.

🔹 Standardized Fit: Precision-engineered with M23 × 1.5 female thread and compatible dimensions (Ø ≈ 96 mm, height ≈ 214 mm) for direct replacement without modifications.

🔹 Prolongs Compressor Life: By filtering harmful particles from lubricating oil, this filter enhances oil quality, reduces wear, and extends the life of bearings and air end components.

Technical Specifications

-

Part Number: 1631011800

-

Filter Type: Oil Filter Element

-

Filtration Media: Inorganic Microfibers (~25 µm)

-

Working Pressure: Up to 25 bar

-

Burst Pressure: 35 bar

-

Bypass Valve Opening: ~1.75 bar

-

Thread: M23 × 1.5 Female Bottom

-

Outer Diameter: ~96 mm

-

Height: ~214 mm

-

Weight: ~1.07 kg

Why Choose Atlas Copco 1631011800 Oil Filter?

✔ Genuine OEM Quality: Ensures form, fit, and function for Atlas Copco compressors.

✔ Optimal Lubrication Protection: Captures dangerous contaminants before they can damage critical parts.

✔ Reduced Maintenance Costs: Helps minimize unplanned downtime by maintaining clean oil circulation.

✔ Extended Equipment Life: Supports longer oil life and fewer replacements when used as part of routine service.

Ideal For

✔ Screw Air Compressors

✔ Industrial Rotary Machines

✔ Heavy-Duty Manufacturing Environments

✔ Preventive Maintenance Programs